Fiat MultiJet II – The next generation Green Diesel engine technology

August 31, 2011 | by techlineinfo.com

Diesel engine was developed by Rudolf Diesel in 1893. It was developed to meet the demerits of gasoline (petrol) engines such as poor efficiency, poor torque etc.

Why Diesel as Fuel? The energy density of Diesel is superior than Petrol. 1 Ltr Petrol contains 34 Mega Joules of Energy at the same time 1 Ltr Diesel contains 38.6 Mega Joules . Additionally the refining process of Diesel is relatively economical. The combination of the energy efficiency of Diesel engines and the Diesel Fuel obviously give more mileage.

However in the beginnings, the applications of Diesel engines were reasonably limited to the high power sector only because of huge size, vibration, Noisy operation, Smoke etc. It was not so popular in personal vehicles. Development in the allied technological fields considerably supported the development of better and efficient Diesel engines. Turbo powered diesel chargers, common rail technology etc are the revolutionary milestones in the history of Diesel engines.

The latest Multi Jet technology developed by Fiat is termed as next generation engine technology. What is Multi Jet engines? What is the technology behind this? Why MultiJet engines are superior than the other engines? Let’s discuss about that .

Fuel Injectors: Before going to MultiJet technology few words about Fuel Injectors. Fuel injectors are one of the most sophisticated parts in a Diesel engine. Fuel injectors are used to inject fuel into the combustion chamber (Cylinder). The fuel injectors are designed to spray the desired amount of fuel into the cylinder in the form of fine mist at the same time it must be rugged enough to bear the high pressure and temperature inside the cylinder. Hence the efficiency of fuel injectors are highly influential in the overall efficiency and performance of an engine.

UniJet Turbo Diesel Engines

In 1997 Fiat unveiled the common rail technology a.k.a uniJet Turbo Diesel (JTD), which was a milestone in the Diesel engine history. Here the electronics joined hands with Mechanical. In conventional Diesel engines the fuel injectors were operated mechanically but the modern common rail technology utilizes Engine Control Unit (ECU) to operate fuel injectors electronically. In common rail technology a common fuel rail supplies fuel to all fuel injectors. In this rail the fuel is stored at a high pressure. Operation of each fuel injectors are controlled controlled Electronically. The outcome of Common Rail technology was remarkable. This technology made noiseless, smokeless, powerful and fuel efficient diesel engines. Most of the car manufacturers adapted this technology and Europe’s diesel car market share increased from 15% to a remarkable 50% .

In 2002, Fiat Group is honored with Economist Innovation Award in the Energy and Environment category for their innovative Common rail technology, which is use by almost every major car maker worldwide.

Multijet Technology

In 2003, the quest of making a much better diesel engine resulted the development of Multi Jet Technology. The uniJet Turbo Diesel (Common rail) technology was upgraded to MultiJet technology. As the name shows, in this advancement the number of injections increased to a total of five which ushered in even more refinement and performance. In 2005 Fiat’s MultiJet 1.3L diesel engine bagged “International Engine of the Year” award.

There’s two main differences in MultiJet technology from its predecessor UniJet engines. One is injector and the other is Electronics Control Unit . In UniJet engine you will find only two injections within a combustion cycle. Means a pre injection (Pilot injection) which raises the temperature and pressure inside the cylinder in order to improve the main stroke. In Multijet engines the main injection is divided into multiple smaller injections(Five injections), which ensure complete efficient steady combustion within the cycle. Here by keeping the amount of diesel burnt in each stroke remain same, the multiple smaller injections at certain intervals within the cycle result smoother, quieter combustion with high efficiency and low emission. All these injections are electronically controlled by evaluating multiple feedback factors such as engine rpm, torque required at a period of time and temperature.

MultiJet II

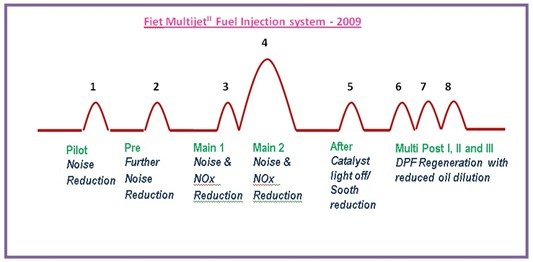

in 2009, Fiat came up with next version of MultiJet engines. MultiJet-II. The ultimate evolution of their own common Rail Technology. In MultJet-1 there were 5 pre injections per cycle but now in this MultiJet II technology, it is increased up to 8 injections pre cycle. By evaluating many variables these injections are precisely controlled to improve the efficiency , fuel economy, power, reduce noise, vibrations and emissions.

In the MultiJet II fuel injectors by Fiat Powertrain Technologies (FPT), the shutters of fuel injectors are hydraulically balanced to avoid reduction in shutter strokes. The new servo valve facilitate the precise control of fuel quantities injected into the combustion chamber. Through this eight consecutive injections with accurate metering is achieved. The “Injection Rate Shaping” (IRS) injection mode results in better combustion control. Through that Noise reduction , Emission control and Fuel efficiency is achieved . This MultiJet II technology is a big step towards the achievement of Euro 6 emission standards.

Advantages of MultiJet Engines

Here the quick list of the advantages of MultiJet Engines

- Great Power and Fuel Economy

- Next generation Emission Standards

- Better Power and Torque

- Less Noise

- Less Vibration

- Improved Reliability

- Less Maintenance

Diesel At the Price of Petrol

Now Fiat has launched an upgrade offer. Buy any Fiat Linea or Punto car today and you could get lucky with a free upgrade to Fiat Multijet diesel technology – for the price of a petrol car. More details visit the official page.

RELATED POSTS

View all